Recombinant technical and therapeutic proteins (biologicals, biopharmaceuticals) are irreplaceable in the food, feed, cosmetics and pharmaceutical industry. Recombinant proteins are predominately produced by fermentation of the gene-of-interest containing bacteria, yeast, insect and mammalian cell cultures in bioreactors, which is associated with high energy and resource consumption. Plants and plant cell cultures can be a sustainable alternative, since their cultivation requires fewer resources and is based on renewable ones. In addition, animal and human pathogens do not replicate in plant cells, which simplifies the requirements for sterile production conditions and thus reduces costs.

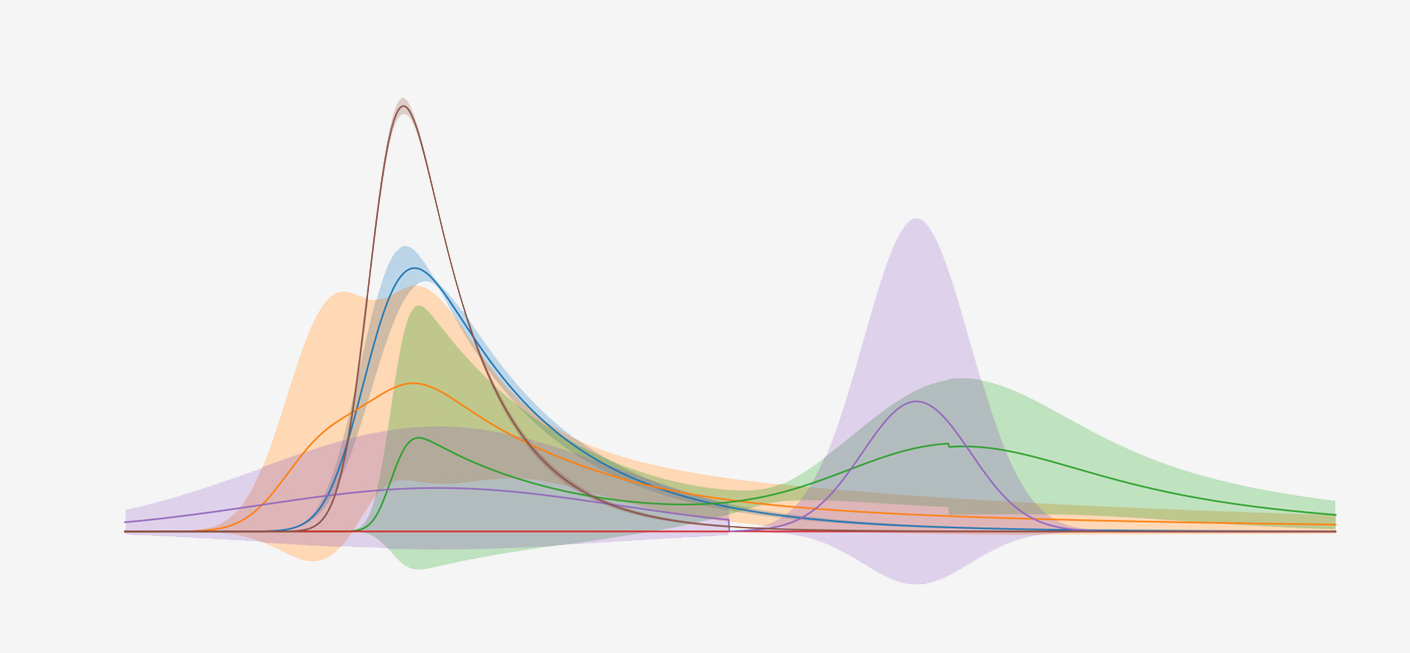

Aiming at a cost-effective production of recombinant proteins in plant cells, the Bioprocess Engineering department has specialized in the development of suitable expression vectors, cultivation conditions for batch, fed-batch and semi-continuous fermentation regimes, extraction protocols and chromatographic purification methods to improve the growth of plant cells and to increase the accumulation levels of the recombined protein as well as to reduce the losses during purification and at the same time to increase the purity. To achieve this, statistical methods such as design-of-experiments (DoE) as well as data-driven, descriptive and mechanistic models are used to predict and specifically optimize suitable conditions for production and purification. In addition, the department deals with process automation and database-based integration and evaluation of the collected data and their utilization to improve the models used. With the optimization of the production conditions (upstream production, USP) and purification (downstream processing, DSP) in combination with process automation, modeling and digitization, the entire process chain in the production of recombinant technical and therapeutic proteins is considered.

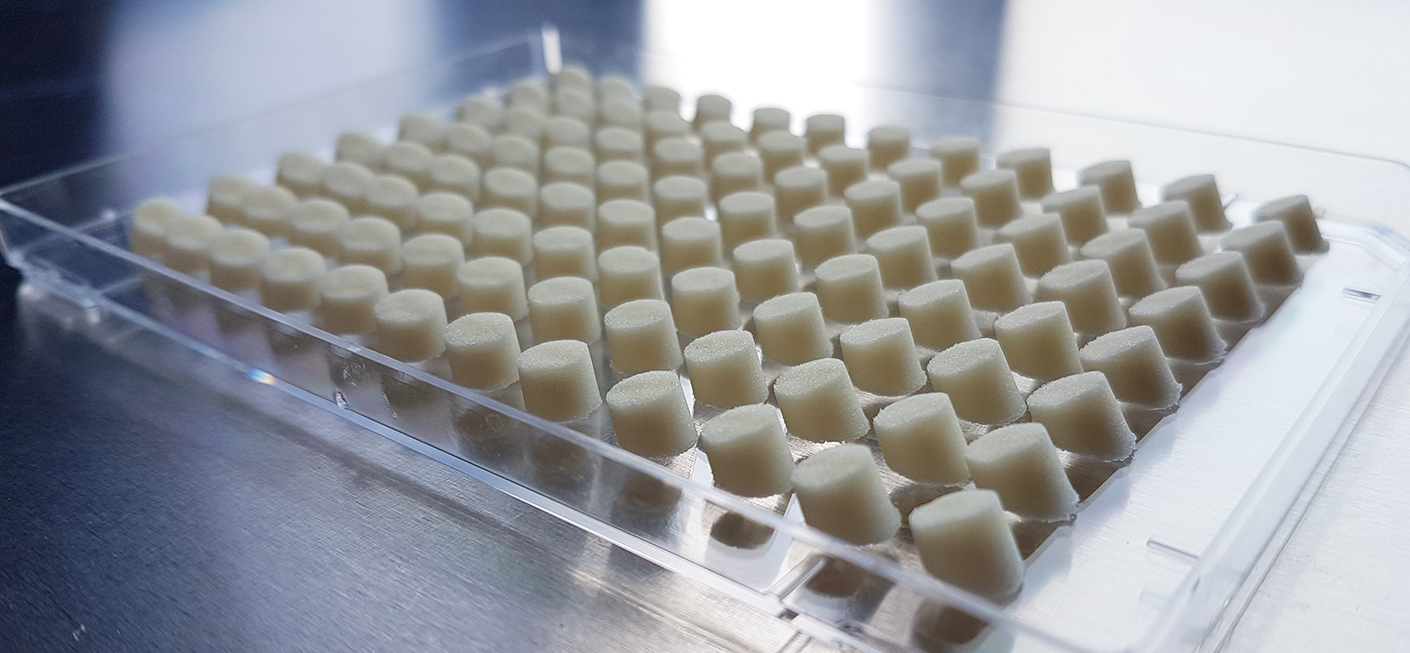

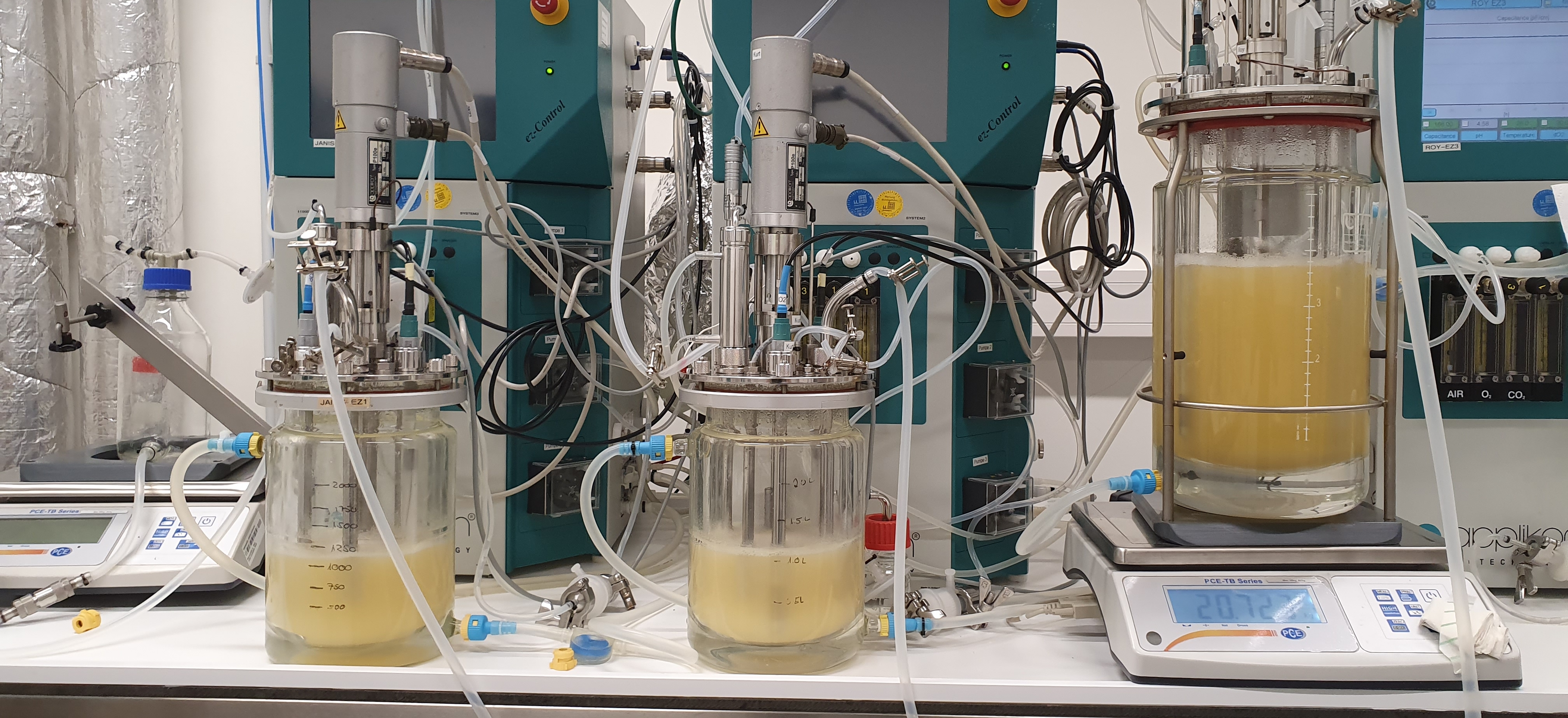

The process development is initially carried out in an automated high-throughput screening system in the microtiter plate format and is then verified on a 1-5 L scale in glass bioreactors, with the processes being designed in such a way that they can be transferred to large scale production and meet the requirements of an industrial production environment such as the food or pharmaceutical industry.

Fraunhofer Institute for Molecular Biology and Applied Ecology IME

Fraunhofer Institute for Molecular Biology and Applied Ecology IME