The synthesis of natural rubber and its main component polyisoprene from individual isoprene building blocks is a central research topic at Fraunhofer IME. The synthesis of shorter isoprene chains, so-called terpenoids, proceeds via the same biosynthetic pathway. The economic importance of terpenoids is enormous. They are in high demand not only as additives in rubber processing, but also for pharmaceutical, agricultural or chemical applications. The extraction from the producing plants poses great challenges and is often accompanied by high energy and resource consumption. Hence, the use of microbial organisms such as baker‘s yeast is coming into focus.

Our yeast platform

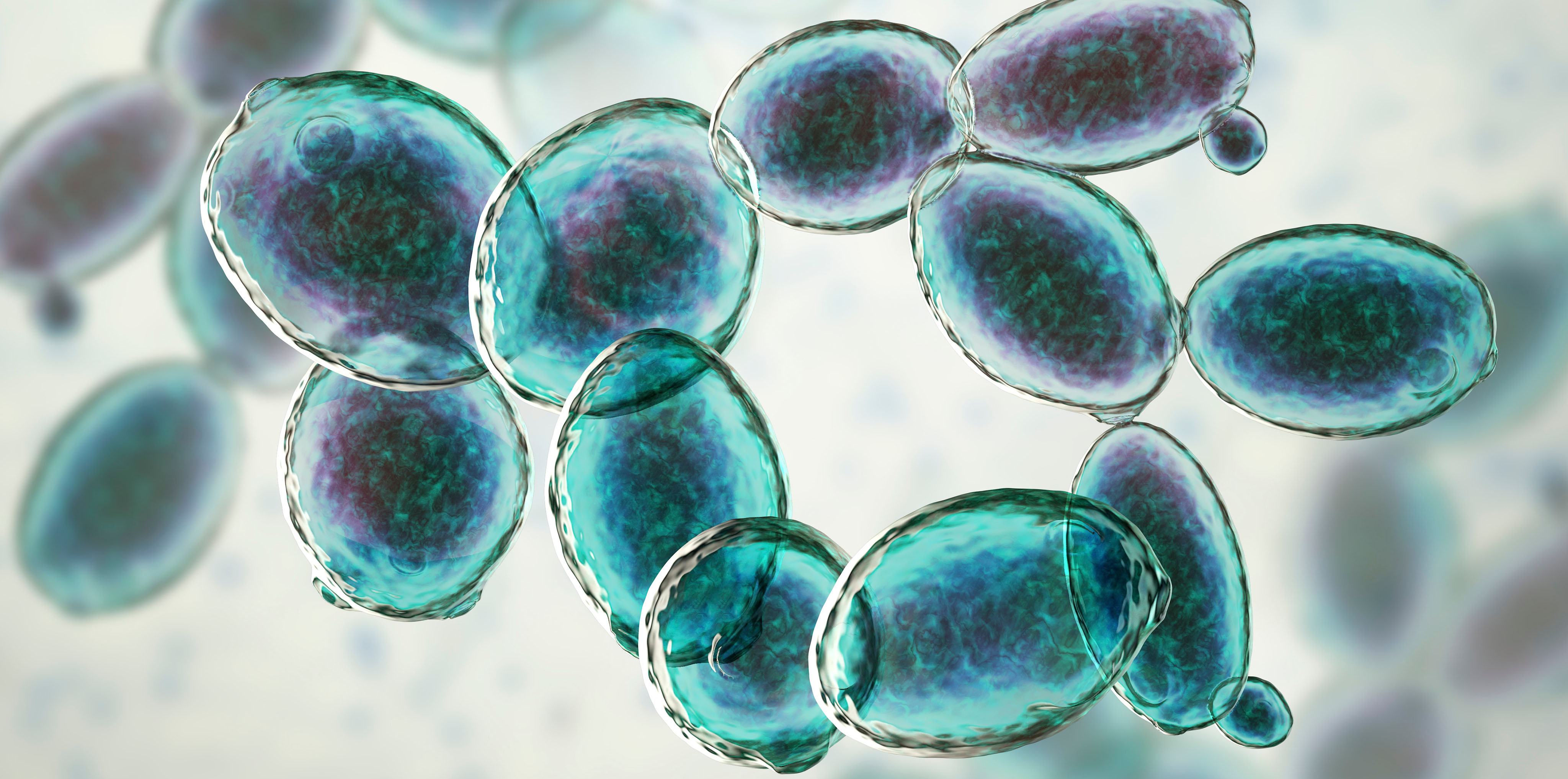

Baker‘s yeasts are unicellular fungi that are usually fast-growing and highly adaptable with regard to their food and environmental conditions and are therefore very well suited for biotechnological processes. In addition, yeasts already contain the ability to produce terpenoid precursors and membrane systems at which the synthesis of the mostly apolar molecules can take place. Using molecular biological methods, Fraunhofer IME has further developed yeasts that accumulate the required precursors in order to produce desired isoprenoid end products in a targeted manner. The yeasts can be cultivated in media of any complexity, such as a medium generated from waste streams from the food industry.

Enzymatic screenings

Various natural and molecularly optimized enzymes for the production or modification of terpenoids can be introduced into the respective adapted yeast platform.

After fermentation and breakdown of cells, the products are measured using analytical methods such as GC-MS, LC-MS or in corresponding enzyme assays in the multimode microplate reader. By means of targeted modifications or laboratory evolution, yields can thus be increased in iterative steps to achieve economic viability for larger productions.

Scale-up

The scale-up of production from laboratory to pilot/technical scale and further to industrial scale is already taken into account during strain development. This enables the use of antibiotic-free, complex media with low energy consumption and high product titers. Flocculation problems are also avoided by appropriate modifications already in the original yeast

Fraunhofer Institute for Molecular Biology and Applied Ecology IME

Fraunhofer Institute for Molecular Biology and Applied Ecology IME