Motivation and Problem

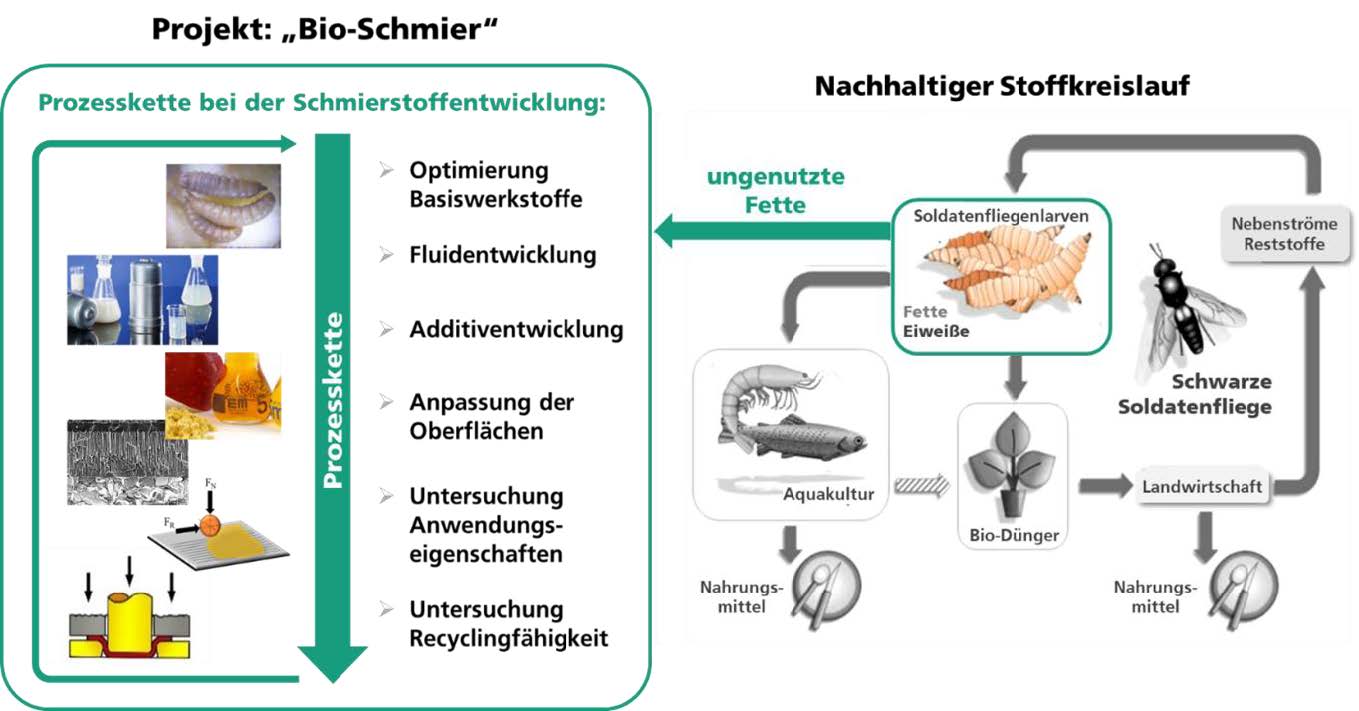

The project consortium aims to develop solutions to the current problems of rising raw material prices and uncertain raw material availability as well as rising energy and process costs through ''bio-lubrication''. Our solution approach addresses the increase of raw material resilience through a previously unused biogenic source - insect fats - as well as the improvement of process and energy efficiency using the example of metal forming. Our platform technology is designed in such a way that it can also be transferred to other raw materials and processes

For some time now, the chemical industry has been confronted with increasing limitations in the area of biogenic fats and oils. This has been further exacerbated by the current crisis in the supply of raw materials. Waste fats and animal fats are no longer available, as they are almost completely used for the production of hydrogenated oils. Many years of research efforts in the field of algae oil for the chemical industry have not yet been successful. Algae oil only plays a role in the food sector or in biogas production. Although large quantities of vegetable oils are available on the world market, they are used almost exclusively in food production or in the fuel sector due to legal requirements. However, the current and continuing supply crisis for fossil raw materials makes the development of competitive, bio-based product alternatives in the chemical industry essential. Ideally, alternative raw materials should be found that can be produced in Europe independently of the fluctuations and risks of the global market. Insect fats could become a suitable alternative in the future. A promising chemical profile speaks in favour of this, which is disadvantageous for food production but very promising for the chemical industry. In lubricant applications, there is the problem of insufficient interaction between lubricants and material surfaces. This mainly results from a lack of coordination between the two systems and leads to unnecessarily high wear, faster tool wear, faster lubricant ageing, higher friction losses and process temperatures. ''Bio-Schmier'' also aims to make a significant contribution to material efficiency and to extending the operating times of media and processes in order to reduce production and energy costs. Insect production can be carried out using domestic residues as a feed substrate, providing a sustainable source of raw materials for oleochemistry.

Fraunhofer Institute for Molecular Biology and Applied Ecology IME

Fraunhofer Institute for Molecular Biology and Applied Ecology IME