Research motivation

Feed production is destroying ecosystems worldwide. Insects represent a high-quality alternative to classic feed. By recycling industrial side streams, insects enable a circular economy and mitigate an emerging protein gap. Fraunhofer IME develops automated production systems to scale competitive production volumes.

Soy demands for livestock farming are a major driver for the ongoing deforestation of the Amazon rainforest. Similarly, fishmeal fed in aquaculture contributes to overfishing of the oceans. With the world's population on the rise and an increasing global demand for meat and fish, new feeds are required to produce more proteins while reducing its environmental impact.

Insects as feed

Insects are highly resource efficient. Compared to mammals, they require a fraction of water and land. As they can even thrive on food waste, insects do not require additional feed. For example, the larvae of the black soldier fly could be used to upcycle the EU’s 88 million metric tons of food waste into high-quality animal protein. This resilient insect could even recover nutrients from manure and sewage sludge.

The protein meal extracted from black soldier fly larvae has a balanced amino acid profile, making it an attractive substitute, particularly for fishmeal. Moreover, the replacement of fishmeal by insect proteins reduces the risk of marine pathogen contamination in aquaculture.

Profitability crucial for market penetration

Worldwide, about half of the consumed fish is produced in aquaculture. Feeds may make up about 50 % of the aquaculture costs and are therefore crucial for its profitability. Consequently, the price of insects must compete with a fishmeal price of about €1,500 per ton.

Small-scale insect production is governed by the feed substrate and labor costs. The feed substrate costs can be minimized by using side streams. According to the law of mass production, increases in production volume can lower the specific production costs. However, economies of scale in large-scale insect production go along with highly priced automated production technology. The required capital expenditures have made investors shy away so far. In addition, organic side streams such as municipal waste occurs in a distributed manner. Their transport to a few centralized factories increases costs and is not sustainable.

Production technology to reduce costs

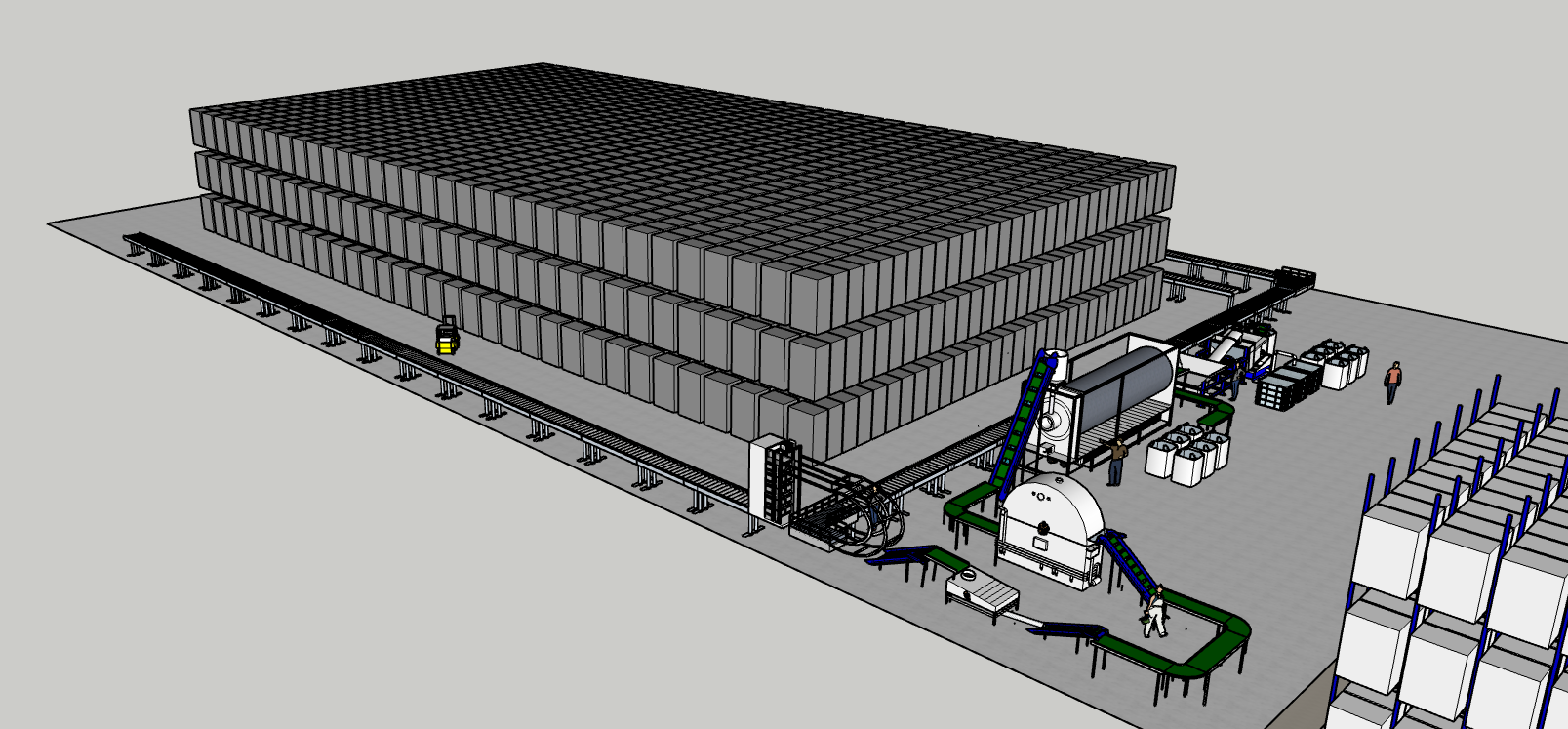

At Fraunhofer IME's Bioresources Division, the development of new production technology for insect farming largely aims at medium-sized enterprises. These include farms, companies in the food industry and regional waste management companies, which typically require low-investment facilities with low personnel expenses in order to be able to utilize side streams locally. To engage successfully in the novel insect farming sector, expert knowledge on insect biology and farming must be available in a simplified and cost-effective manner.

To reduce complexity, insect production can be divided into the reproduction and the fattening of larvae. Reproduction can be outsourced so that the facility focuses on the utilization of side streams in the fattening process. A production control system regulates environmental parameters such as temperature, humidity and oxygen to ensure ideal conditions. Observation of larval weight gain using computer vision algorithms enables fully automated monitoring. Merging sensor data in cloud software and its evaluation employing machine learning guarantees optimized process control for each substrate and situation dependent instructions. A digital twin – a virtual model of the insect life cycle – can predict the protein and fat content, as well as the amino acid profile. Thereby controlling the composition of the insect larvae, the feed can be utilized to support animal growth and health. Thus, the antibiotics application is reduced, in addition to conserving bioresources.

Fraunhofer Institute for Molecular Biology and Applied Ecology IME

Fraunhofer Institute for Molecular Biology and Applied Ecology IME